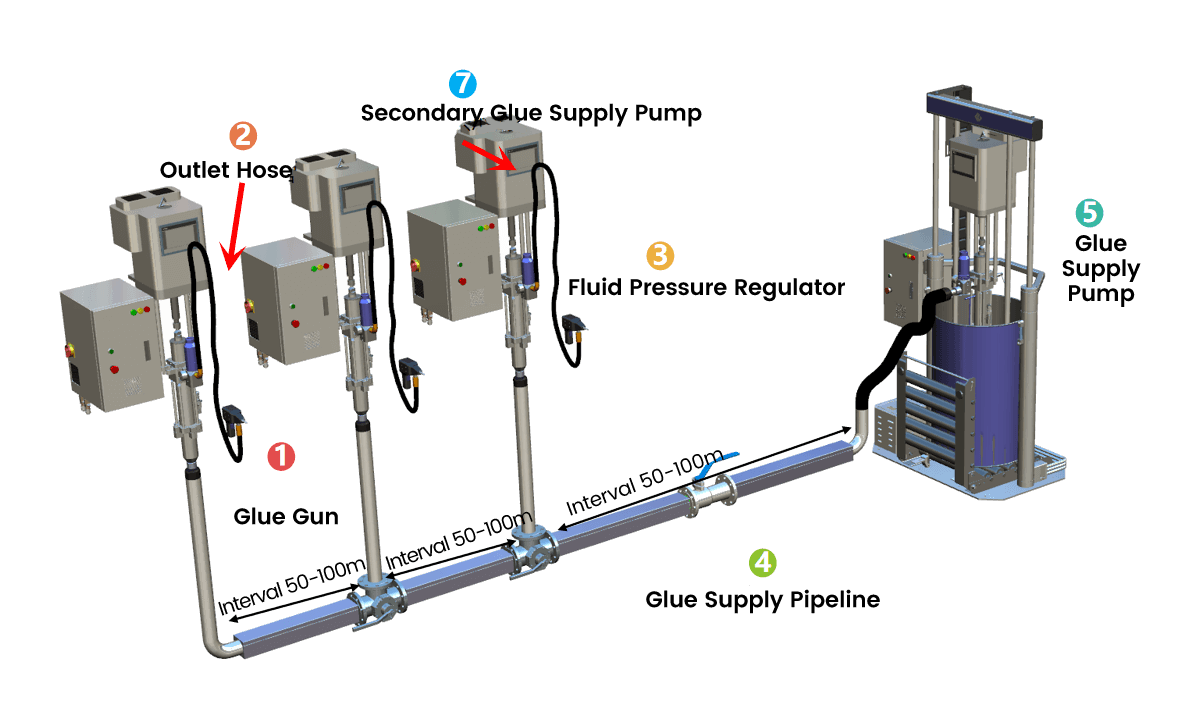

Multi-Pump Long-Distance Glue Supply System

When the glue pump and the final glue application are located far apart, a multi-stage glue supply system is used to achieve long-distance glue application. When the primary glue pump’s main pipeline reaches a certain location, it connects to a secondary glue pump for boosting pressure before finally delivering the glue to the application area. This multi-pump long-distance glue supply system is suitable for glue application at multiple workstations. Each glue application line uses a high-pressure fluid regulator to regulate the pressure to meet the glue application process.

What You Get with It

- Increased Productivity

Our dispensing solutions for paint shop contribute to a highly productive manufacturing process - Repeatable high quality

We strive for perfect dispensing results and repeatable high-quality applications - Easy to Use

Our system solutions are easy to set-up, easy to use and easy to maintain

System Components

Glue Pump

Glue pumps are divided into primary and secondary pumps. Primary pumps are no different from ordinary glue pumps; secondary pumps have fewer pressure plates, and the glue inlet is directly connected to the glue delivery pipe of the primary pump. After pressurization, the glue is delivered to the glue application area through the pipe.

High-pressure fluid regulators

Pressure reducing valves are used to adjust the pressure of the medium, allowing it to be transmitted smoothly. There are many types of pressure reducing valves, and you can choose one based on different scenarios. Generally, pressure reducing valves are installed at the glue pump and glue gun for pressure regulation.

Pipeline

The air pipe uses a high-pressure air pipe; the others are colloid conveying pipes, which are resistant to high pressure and heating.

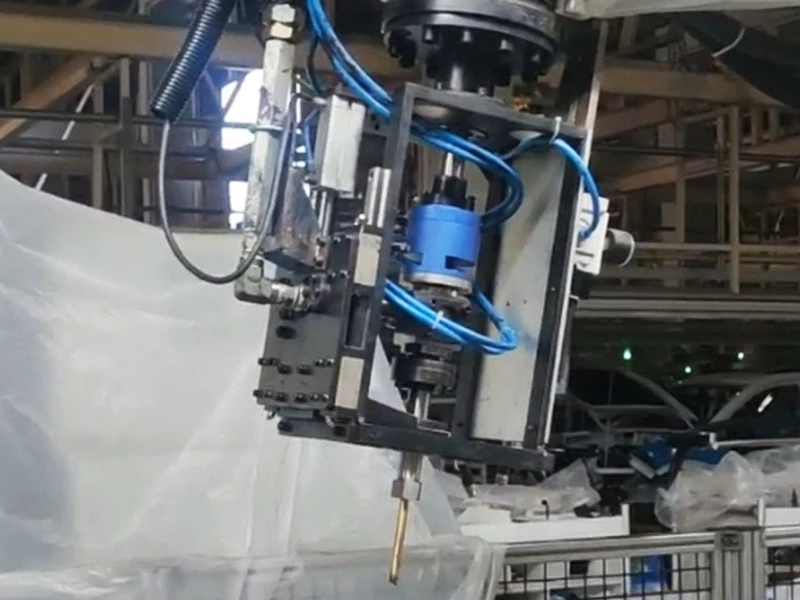

Glue Gun

This glue supply system is used in manual gluing scenarios. Depending on the usage, it can provide ordinary cold glue guns or heated glue guns.