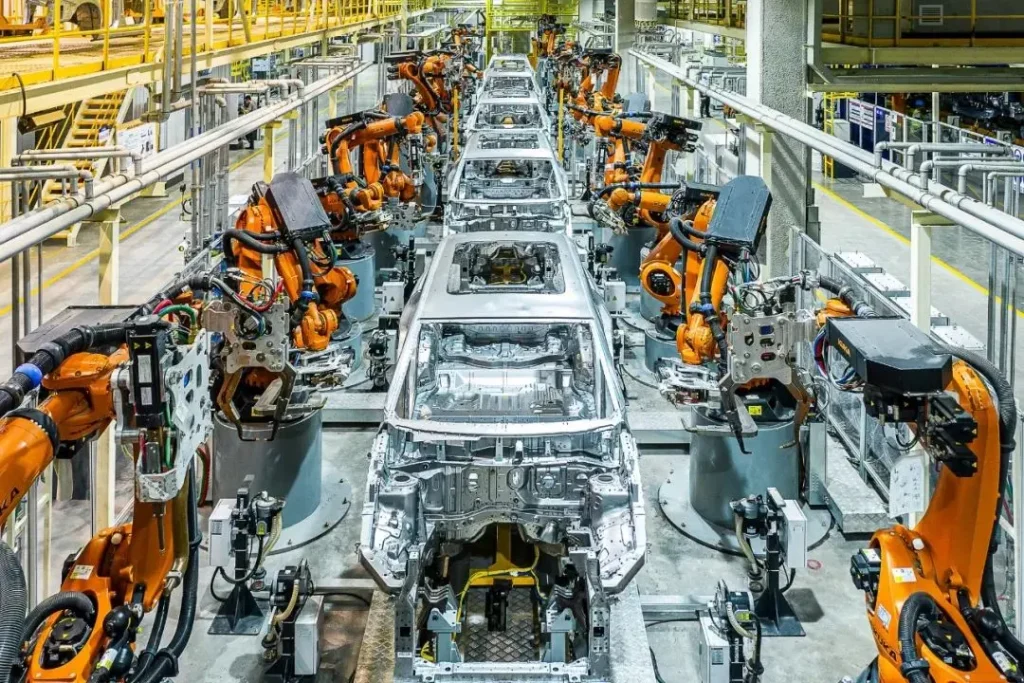

Chang’an Liangjiang No. 3 factory assembly

Customer case: Chang’an Liangjiang No. 3 Factory × Chongqing Hongguang Electromechanical Equipment Co., Ltd

Welding workshop sealing system mechanical pressure reducing valve upgrade project

Project background

Liangjiang and Sanfactories encountered technical bottlenecks when undertaking BYD’s CTB battery chassis project in 2025:

Hongguang Machinery Solution (Dual-Core Drive System)

(1) HG-MRV55 mechanical pressure reducing valve

(2) HG-HT200 manual smart glue gun

Implementation process

2025.02.20-03.08

Extreme temperature change test (-20°C~80°C)

2025.03.13

DNV GL certified

2025.03.14

The daily production capacity exceeded 18,000 pieces

Comparison of core results

| Key indicators | Original system | After the renovation | Industry standard |

|---|---|---|---|

| Pressure stability | ±12% | ±0.4% | ±5% |

| Glue ready time | 180 seconds | 30 seconds | 60 seconds |

| Environmental adaptability | 15-35℃ | -20℃~80℃ | -10℃~50℃ |

“In the 80°C high temperature simulation test, Hongguang system Mechanical compensation mechanism The standard deviation of the output pressure is only 0.007MPa, and the error of sealant extrusion is < 0.3% for 72 consecutive hours. ”

—— Li Mingyang, Senior Engineer, Equipment Technology Department, Chang’an Liangjiang Factory