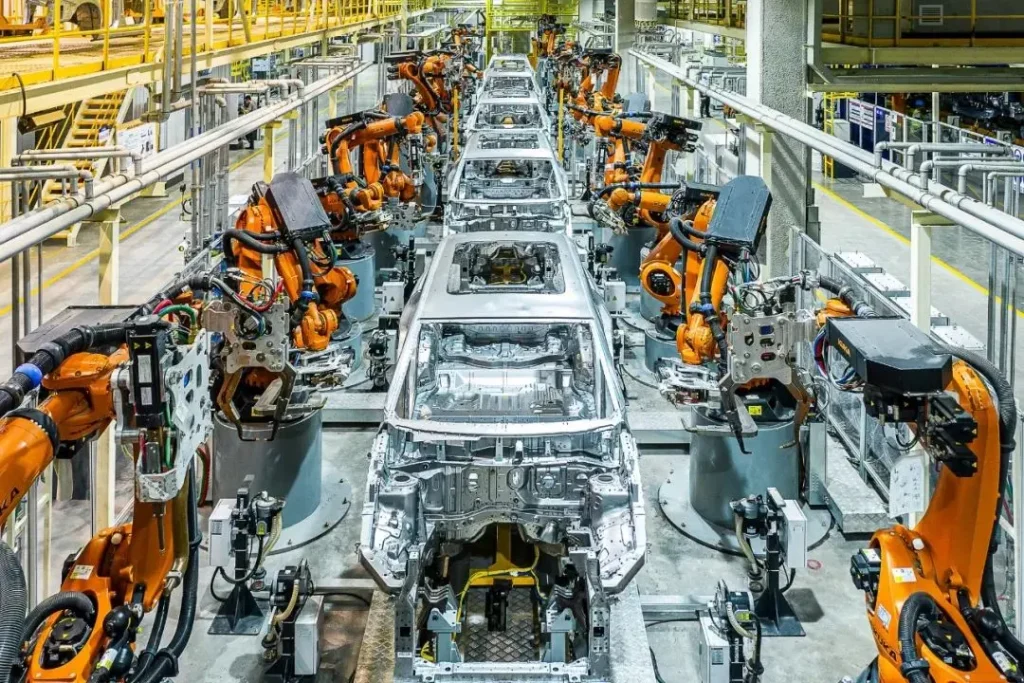

Welding workshop of Chang’an Liangjiang No. 3 Factory

Customer case: Yangtze River Liangjiang No. 3 Factory × Chongqing Hongguang Electromechanical Equipment Co., Ltd

Welding workshop 318 project pneumatic gluing system upgrade project

Delivery time: March 14, 2025 15:50 (Friday, the fifteenth day of the second lunar month, the Year of the Snake)

Project background

The Liangjiang plant faced special challenges when undertaking the Volkswagen MEB platform battery tray welding and sealing project:

Hongguang pneumatic system solutions

(1) HG-QDR55 pneumatic pressure regulation system

(2) HG-MH2000 manual smart glue

Project milestones

| Key indicators | Before the renovation | Current level | German standard |

|---|---|---|---|

| Weld seal pass rate | 92.3% | 99.98% | 99.5% |

| Glue change time | 45 minutes | 8 minutes and 30 seconds | 20 minutes |

| Glue response speed | 8-12 seconds | ≤ 1 second | 3 seconds |

“In the 0.3MPa low-voltage test, Hongguang system Dual-channel dynamic compensation technology The pressure fluctuation was only ± 0.15%, and the permeability of the sealant was tested for 12 hours < 0.01 μL/min. “

—— Wang Zhenyu, Chief Engineer of Liangjiang Factory Welding Research Institute