Chongqing digital model Yongchuan

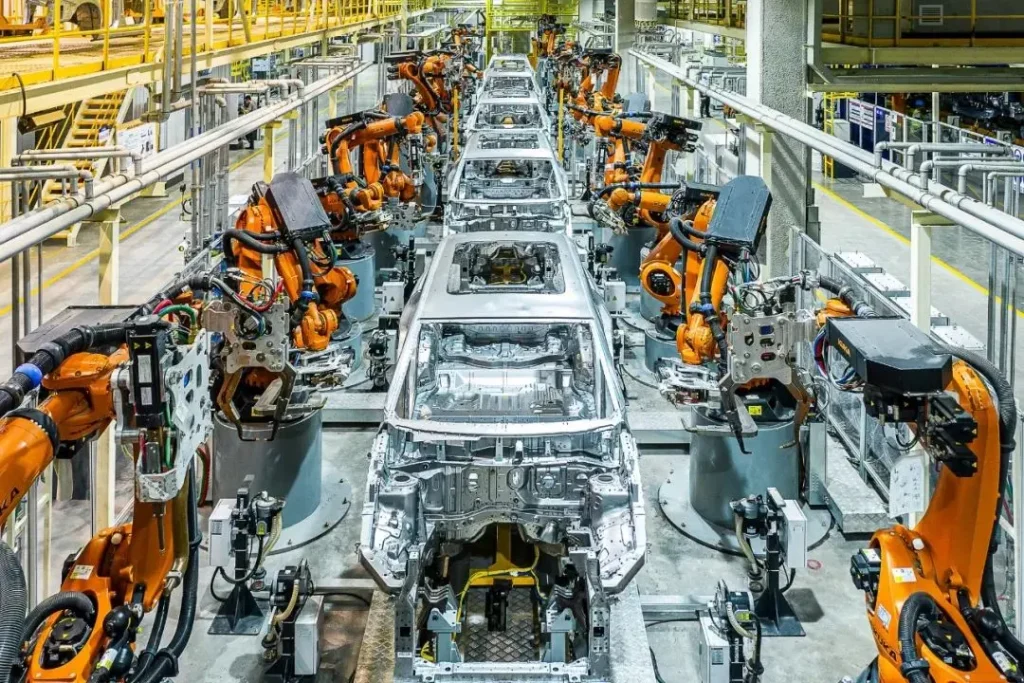

Customer case: Chongqing Digital Mold Yongchuan × Hongguang Group automotive gluing equipment

The whole process of heating, one pump and two guns technology empowers the efficient and intelligent manufacturing of the Great Wall P01 project

Customer background

As a leading auto parts manufacturer in southwest China, Chongqing Digital Mode Yongchuan (2025 strategic partner) undertakes the upgrading of the gluing process of Great Wall Motor’s P01 new platform model, and needs to solve core pain points such as rubber waste (8%+) and temperature control fluctuations (±3°C).

Technological breakthrough highlights

Quantify the results

| index | Before the renovation | After the renovation | Lift rate |

|---|---|---|---|

| Gluing a single machine takes time | 120 seconds | 75 seconds | +37.5% |

| Utilization rate of compounds | 91.2% | 98.6% | +8.1% |

| Overall Equipment Effectiveness (OEE) | 76.3% | 93.8% | +22.9% |

Customer testimonials

“In the Q1 mass production sprint stage of 2025, [your company] equipment has achieved zero-failure operation for 28 consecutive days, and the quality of the glue seam has passed the 0.15mm laser detection of Great Wall Motor, far exceeding the industry standard.”