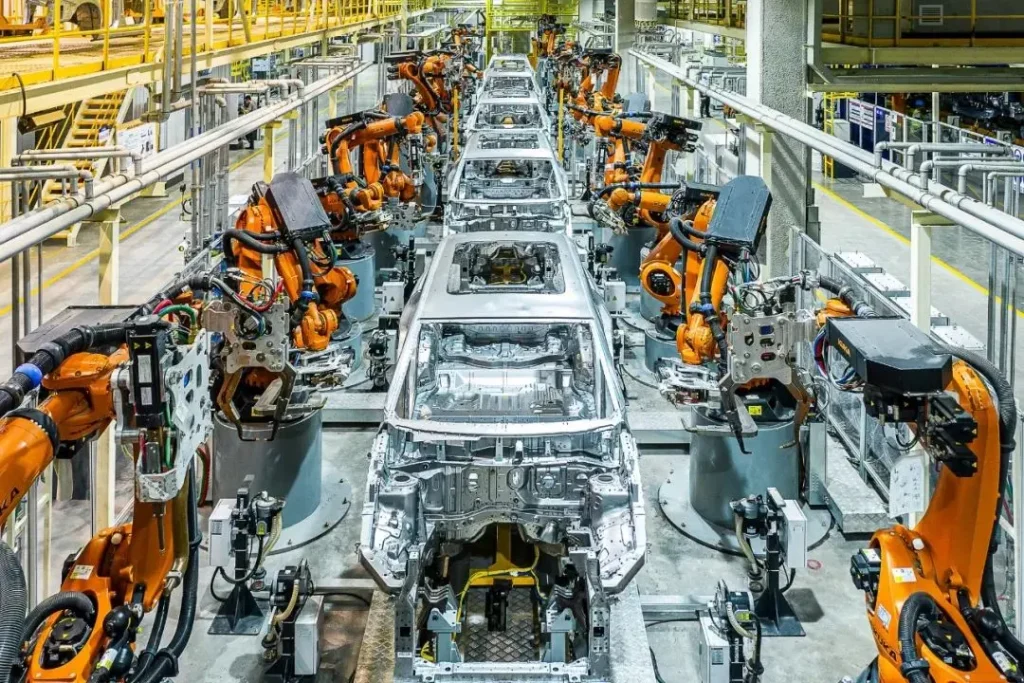

Chongqing Tenghai Nanjing base

Customer case: Chongqing Tenghai Nanjing Base × Chongqing Hongguang Electromechanical Equipment Co., Ltd

Compact gluing system integration solution

Delivery time: March 14, 2025 15:45 (Friday, the fifteenth day of the second lunar month, the Year of the Snake)

Project background

Tenghai Nanjing Base encountered technical bottlenecks when undertaking the electric drive shell sealing project of Xpeng Motors in 2025:

Hongguang system architecture (three-in-one solution)

(1) HG-5G intelligent rubber pump system

(2) HG-PRS pneumatic pressure regulator

(3) HG-MicroHeat Micro Heating Glue Gun

Implementation process

2025.01.20-02.05

High Frequency Pulse Test (100Hz)

2025.03.01

Passed explosion-proof certification

2025.03.14

The monthly production capacity exceeded 80,000 pieces

Comparison of core results

| Key indicators | original system | After the renovation | Industry benchmark |

|---|---|---|---|

| Continuity of glue supply | 0.8 times per hour | 300h continuous glue breakage | 0.5 times/hour |

| Glue thickness CPK value | 0.95 | 2.08 | 1.55 |

| Energy consumption level | 7.2kW·h | 3.8kW·h | 5.5kW·h |

“Under 100Hz high-frequency conditions, the Hongguang system Three-plunger staggered compensation technology The flow fluctuation was completely eliminated, and the standard deviation of the adhesive layer thickness was stable at 0.012mm, setting a new industry record. ”

—— Director Zhang Haoran, Process Engineering Department of Tenghai Nanjing Base