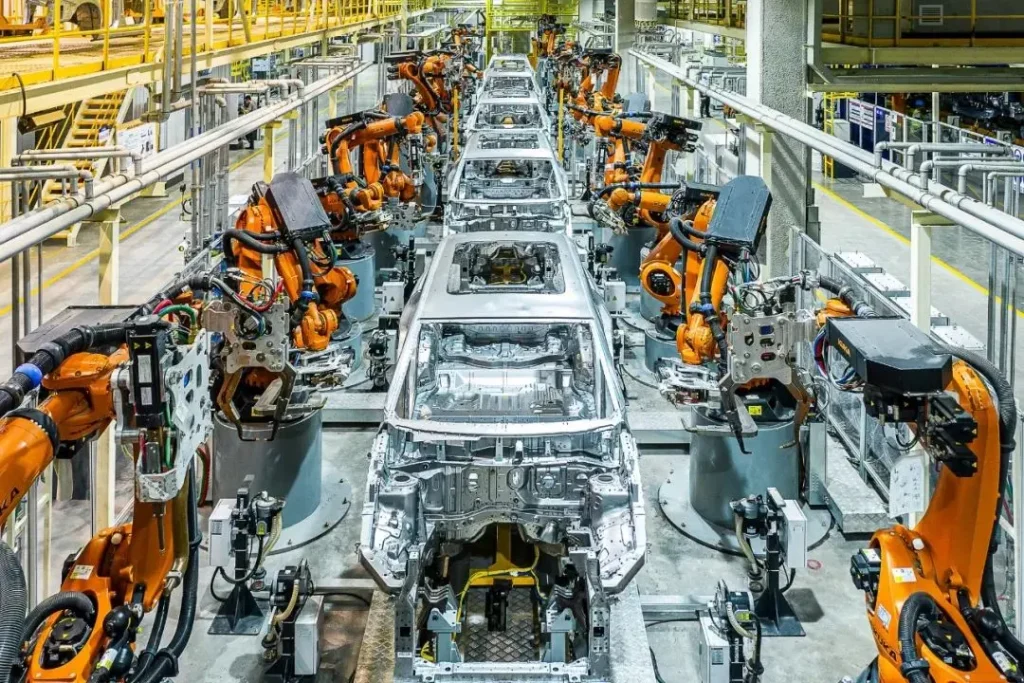

Chongqing Zhixin Anhui base gluing transformation

Customer case: Chongqing Zhixin Anhui Base × Chongqing Hongguang Electromechanical Equipment Co., Ltd

55 gallon large-capacity gluing system intelligent upgrade project

Delivery time: March 13, 2025 18:05 (Thursday, the 14th day of the second lunar month, the Year of the Snake)

Project background

Zhixin Anhui base will face industry pain points when undertaking the Li Auto new generation battery pack project in 2025:

Hongguang system architecture (trinity solution)

(1) HG-55G high-flow rubber pump system

(2) HG-QM3000 high-precision quantitative machine

(3) HG-DH2000 double-pass heating glue gun

Implementation process

2025.01.15-02.10

Verification under -40°C extreme cold conditions

2025.02.28

CE certified

2025.03.13

The single-line production capacity exceeded 4,500 pieces/day

Comparison of core results

| Key indicators | Before the renovation | Current level | Top 5 in the industry |

|---|---|---|---|

| Continuity of glue supply | Break the glue 15 times per hour | Continuous operation for 200h without breaking | Average 5 times/hour |

| Gluing accuracy CPK | 1.02 | 2.15 | 1.68 |

| Production beats | 42 seconds/piece | 29 seconds/piece | 35 seconds/piece |

“In the simulated -40°C extreme cold test, Hongguang systemThermodynamic compensation modelThe leveling of the compound remains stable, and the standard deviation of the adhesive thickness is only 0.018mm in 100,000 cycles. “

—— Dr. Chen Liwei, Intelligent Manufacturing Center, Zhixin Anhui Base