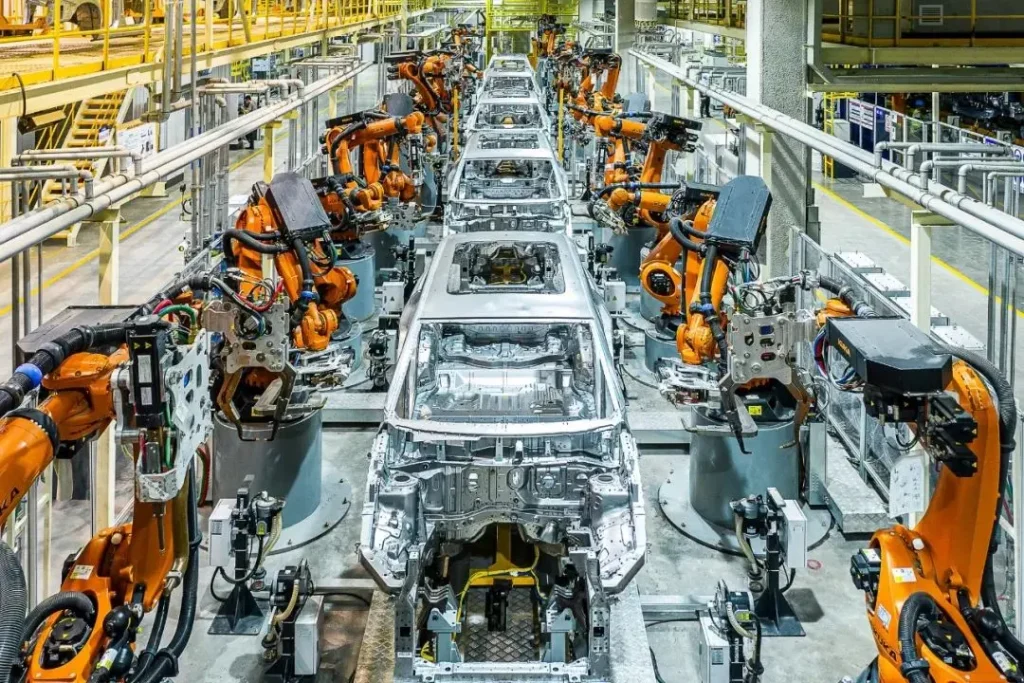

Transformation of gluing system from Chongqing to Xindingzhou base

Customer case: Chongqing Zhixin Dingzhou Base × Chongqing Hongguang Electromechanical Equipment Co., Ltd

Intelligent upgrade project of new energy battery pack gluing system

Project background

When the Zhixin Dingzhou base undertakes the CATL Kirin battery module project in 2025, it encounters three major challenges:

Hongguang core solution

(1) HG-PQAS pneumatic precision pressure regulation system

(2) HG-SmartHeat intelligent temperature control applicator gun

Project milestones

2024.12.25-2025.01.10

Simulation test under extreme cold conditions (-30°C)

2025.02.28

UL safety certification

2025.03.13

The daily production capacity exceeded 3,000 pieces

Comparison of core results

| Key indicators | Original system | After the renovation | Industry Top 3 |

|---|---|---|---|

| Thickness Consistency (CPK) | 0.92 | 1.78 | 1.45 |

| Thousands of pieces of rubber are consumed | 15.8kg | 14.2kg | 15.0kg |

| Abnormal response speed | Manual intervention (5-8 min) | AI Self-Adjusting (≤8s) | Equipment alarm (1-3min) |

“When dealing with the extremely cold environment of -30°C, Hongguang systematicTemperature chain compensation algorithmThe fluidity of the compound remains stable, and the deviation of the thickness of the 48-hour continuous production is only ±0.03mm, which far exceeds the design requirements. “

—— Li Bo, President of the Technology Research Institute of the Xindingzhou Base