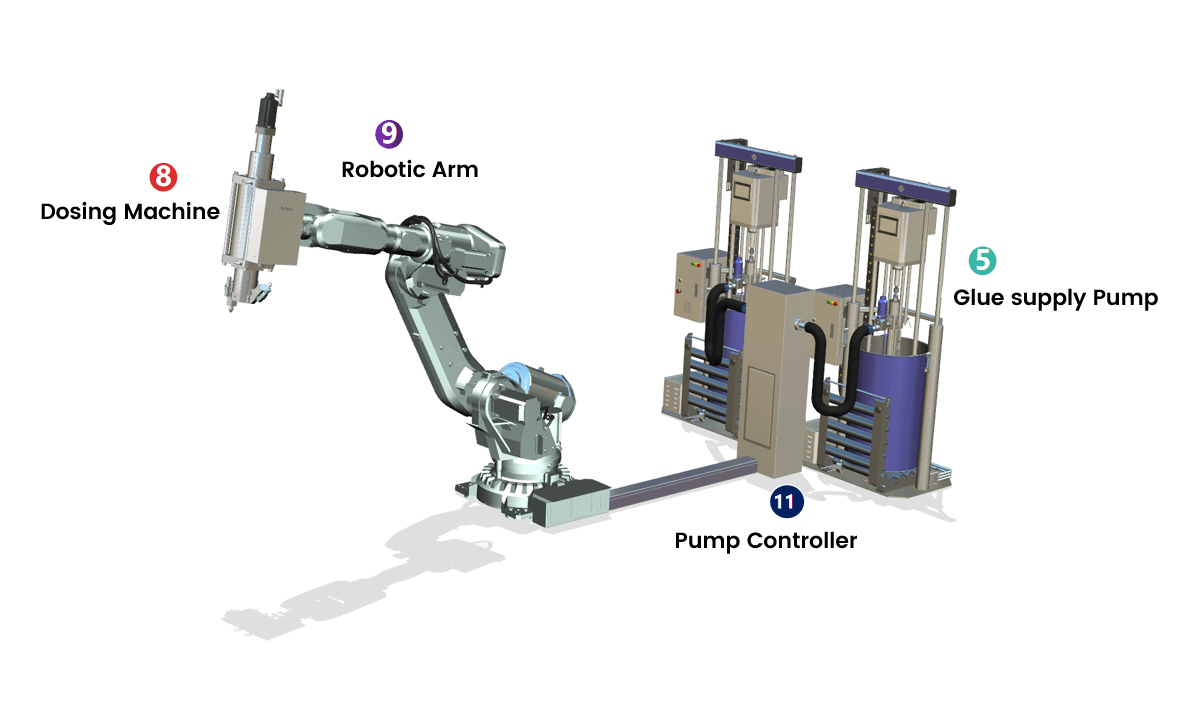

Double Pump Robotic Arm Glue Supply System

This system is suitable for automated automotive gluing. The glue supply system integrates with a robotic arm, freeing up manual labor and improving work efficiency. It comprises a glue pump, pressure reducing valve, piping, a robotic arm (control system), and an automatic gluing gun. Typically, after the workpiece is placed in place, the robotic arm applies glue according to a programmed trajectory.

What You Get with It

- Increased Productivity

Our dispensing solutions for paint shop contribute to a highly productive manufacturing process - Repeatable high quality

We strive for perfect dispensing results and repeatable high-quality applications - Easy to Use

Our system solutions are easy to set-up, easy to use and easy to maintain

System Components

Glue Pump

The glue pump is the basic unit of the glue supply system, providing sufficient pressure for the glue medium. Our glue pump has a pressure ratio of 68:1, and you can choose a 5-gallon or 55-gallon glue pump according to your needs. When supplying two guns, the glue pump’s pressure supply capacity must meet certain requirements.

High-pressure fluid regulators

Pressure reducing valves are used to adjust the pressure of the medium, allowing it to be transmitted smoothly. There are many types of pressure reducing valves, and you can choose one based on different scenarios. Generally, pressure reducing valves are installed at the glue pump and glue gun for pressure regulation.

Pipeline

The air pipe uses a high-pressure air pipe; the others are colloid conveying pipes, which are resistant to high pressure and heating.

Robotic Arm

Various types of robotic arms can be used

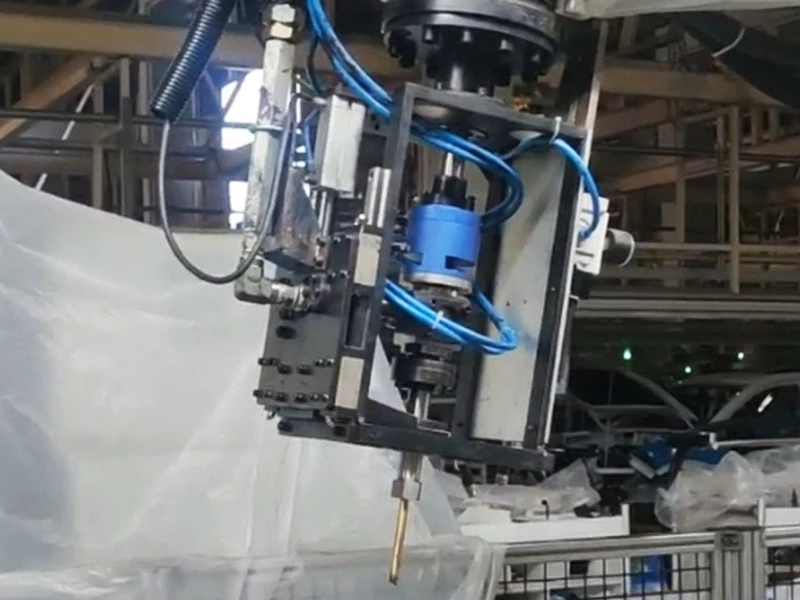

Glue Gun

The glue supply system uses an automatic glue gun. The type of glue gun used varies depending on the product being coated.

- GA9000/GA6000: Suitable for welding and assembly workshops

- GV3W Series/GV3558/G3WD00: Suitable for painting workshops

- GR400 Series: Suitable for assembly workshops